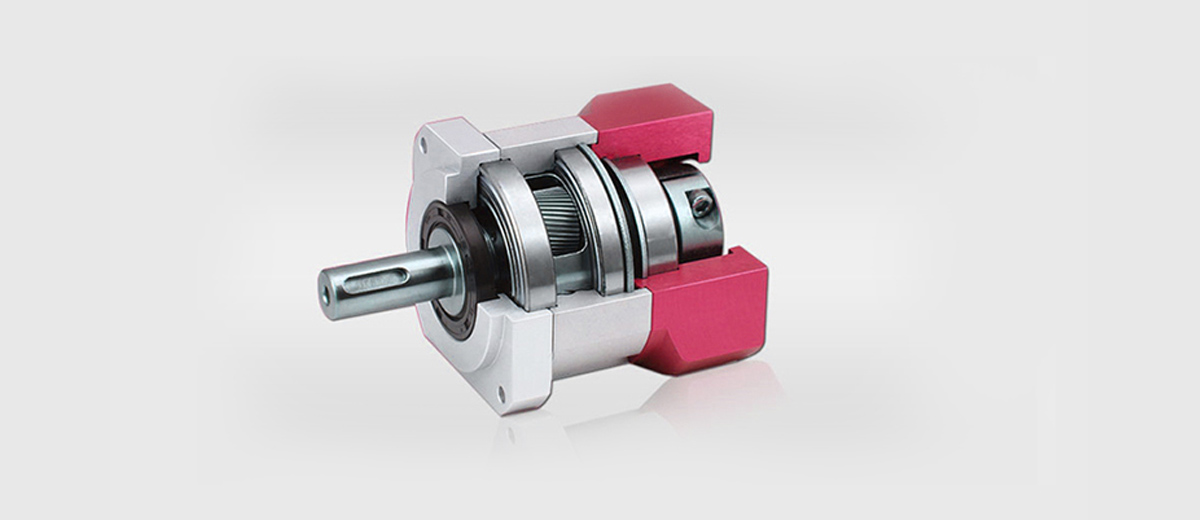

Precision: It can be accurate to 0.001mm, with teeth meshing.

Wear resistance: Thermoplastic materials are widely used to enhance the wear resistance and life of plastic gears.

Stable: precision injection molding, stable size, quality assurance. Customization: According to customer needs, provide plastic gear processing services.

National standard, American standard, German standard, European standard are complete, can be customized on demand

Lingrui Machinery, teach you to choose the right manufacturer

Choose the right manufacturer, save worry, trouble and money

The size of our gears is very compact, and the transmission efficiency is very high. The gears manufactured through multiple layers of strict technology are durable and have high precision and are not easy to jump teeth.

Starting from the parts, there is no key equipment such as three-coordinates and gear measuring instruments, and it is impossible to qualify the parts and accessories, resulting in poor accuracy and high noise after assembly.

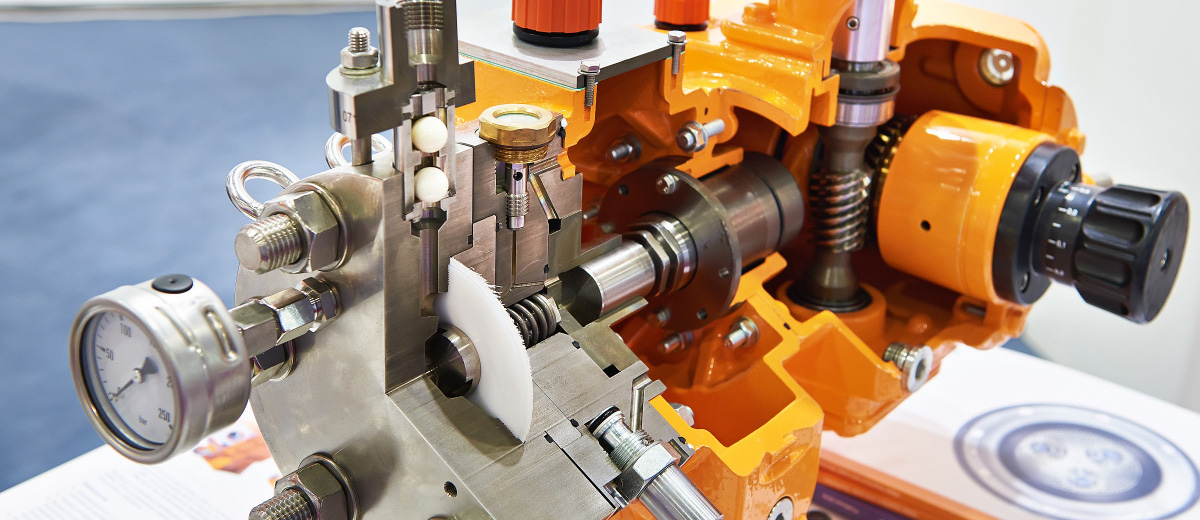

It has high strength, large torque, good comprehensive mechanical properties, good lubricity, easy molding, noise reduction and shock absorption.

In order to make the picture cheaper, the materials used did not meet the national standards. As a result, the quality of the products made is seriously unqualified.

The inner holes, keyways, screw holes are blackened, galvanized, etc. Lingrui Machinery has advanced technology, superb craftsmanship, and high-quality details

Insufficient financial strength, no core research and development capabilities, insufficient processing equipment, and outsourced processing of spare parts. Lead to lengthened construction period

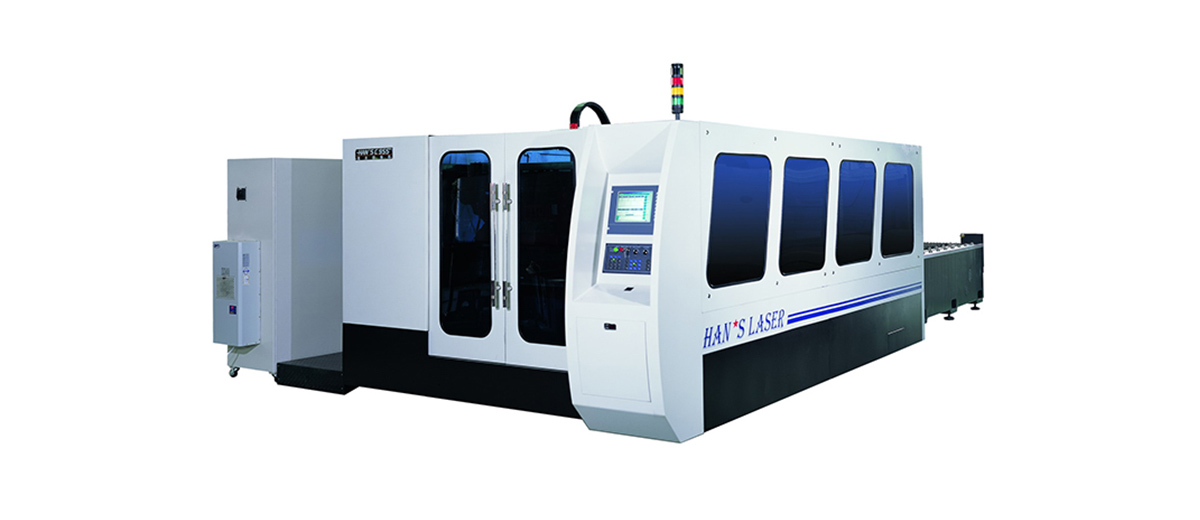

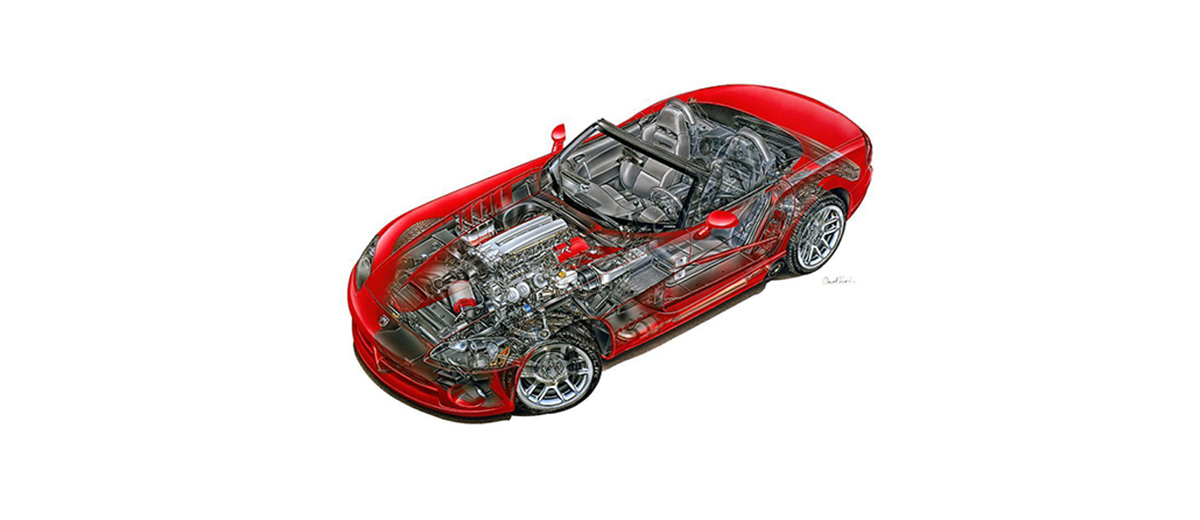

Our products are widely used in textile machinery, chemical machinery, electronic equipment, packaging machinery, printing and agricultural machinery, automation equipment, logistics equipment and other fields.

The scope of application of the same industry can only be applied to some bicycles, daily use, electronics, etc., and it is impossible to make large-scale equipment gear products. The scope of application is limited

Every customer is endorsing Lingrui Machinery

减速机案例Reducer case

数控机床案例CNC machine case

机器人案例Robot case

医疗器械案例Medical device case

汽车案例Car case

油泵案例Oil pump case

更多案例More cases

Good quality control, for your needs, worry-free purchase

Hardware forging for more than 10 years, the products are mainly high-end products

90% is used for long-term export to Europe, the United States and other places, and it is a secondary supplier of famous brand enterprises

Long-term cooperation with well-known companies such as Dahua and Toyota is your choice of confidence

Provide drawing analysis services and guiding suggestions

Tailor-made solutions for customers

We are in hot forging, cold forging, 3D forging, CNC machining

Have extensive expertise and rich manufacturing experience

Now we have more than 50 sets of various CNC processing equipment

Professional technology, R & D team has 50 people.

15-20 days for molds and samples, 7-10 days for mass production。

All our production strictly complies with ISO 9001:2008

IATF16949: 2016 system certification.

Worry-free return and exchange, if the product has quality problems,unconditionally return and exchange and be responsible for related costs One-to-one project follow-up and docking are carried out by dedicated personnel, and timely response to customer feedback problems Intimate after-sales team, quick response online 7x24 hours

One-stop service, saving time and effort

Perfect equipment system, guarantee the quality of "pipe" and worry-free

Focus on Lingrui Machinery, pay attention to new trends in the industry

When processing and producing bevel gears, it is very important to get the key p...

DetailsWhen processing and producing bevel gears, it is very important to get the key p...

Learn more about Lingrui Machinery

Lingrui Machinery Co., Ltd. is an enterprise specializing in the research and development, manufacturing, production and sales of helical gears, straight bevel gears, quasi-hyperbolic gears, worm gears and other transmission accessories. The company currently has domestic and foreign "CNC spiral bevel gear grinding machines , CNC spiral bevel gear milling machine, straight bevel gear planer, vertical CNC machining center, CNC lathe, internal and external cylindrical grinder, gear measuring and display center, proofreading machine and other professional equipment. It can produce modulus M0.5— M10 gear; and accept the customization of non-standard high-precision spiral bevel gears. The products are sold at home and abroad, and there are several professional sales and service centers. We will provide you with technical consultation and full gear design products at any time.

....